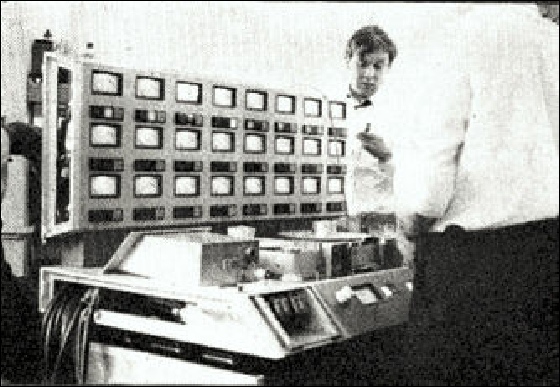

Unitrack Model Uni-24 Tape Machine

Message Board - Unitrack Uni-24 Tape Machine - General Discussion

|

The Unitrack 2” tape deck had twin capstans with a DC servo controlled printed armature capstan motor made by Printed Motors Ltd in Fleet Hampshire. The servo motor drove the right capstan directly. The two capstans were coupled together by a flat mylar belt. |

|

Independent servo controlled AC reel motors controlled tape tension for playback and wind. Two magnetic amplifiers controlled the substantial AC reel motors. The input of each amplifier was fed from a light dependant resister (LDR). A lever beside each idler roller moved a shutter between a light source and the LDR changing the motor current as the tape tension varied. In Edit mode, it was possible to shuttle the tape back and forth with just a finger on either tension sense arm. The deck design allowed a straight tape path for

high-speed winding without the usual static tape guides to keep the tape

away from the heads. Even the playback tension control levers had solenoids so

they could swing out of the way at full speed. The audio electronics were built onto a single card per channel. The design was an unsophisticated NAB playback amp, based around a 5534, with a simple record amp, making full use of the unitrack’s low impedance record heads. Each board had a unitrack impedance matching transformer to couple the record and replay head to the amp for tape or sync playback. The cards were connected to a serial data bus. A latch on the board controlled cmos switches and a relay for sync/line/record etc. We used the original bias oscillator and lifted the bias & erase amp and bias-trap designs from the unitrack blueprints. A machine control board using two 6522 PIO chips drove the channel selection & control bus and the remote control. It connected to another board with numerous relays for the brakes and motor controls. In the remote control box, RS422 data

from serial o/p of machine control board drove a MM5450 34 segment LED driver

that multiplexed the LEDs and scanned Switches back to the controller board. The

control surface had a 0-9 keypad, 24 channel select buttons and LEDs for

Tape(replay), Line, Record, Mute. An ALL select button, Tape, Line, Record and

Mute Master buttons. Auto-locate, REW, FWD, PLAY, STOP, REC, a

multi-digit 7 segment display plus Six soft functions (for auto locate

positions etc.) The control firmware was developed on a BBC B computer using the 1Mhz port to drive machine control board. It was all written in 6502 assembler code. The first version ran sometime in march or april 1988 using the BBC B as a controller. Firmware URV 1.23 (3.6KB of machine code), burned to a 8K eprom, included a variable speed wind function, an auto-locate (which learned the machine dynamics to speed-up locating) Foundational text and pictures courtesy of Bill Todd. |

Unitrack Uni-24 Tape Machine

Do you have content, to add, about the Unitrack Uni-24 Tape Machine or associated topics? Please feel free to Share it, here!

Return from Unitrack Uni-24 Tape Machines to Magnetic Tape Recorders and Reproducers Return from Unitrack Uni-24 Tape Machine to History of Recording - Homepage |